Article published on LegnoLegno News Issue October 2013.

A good idea to change process

In a market of the wooden fixtures where competition is increasing, it is essential for big and small companies to industrialize more and more the production process reducing costs. How to find a junction system for doors and windows that would be compatible without compromise with the entire production process?

Need and vision

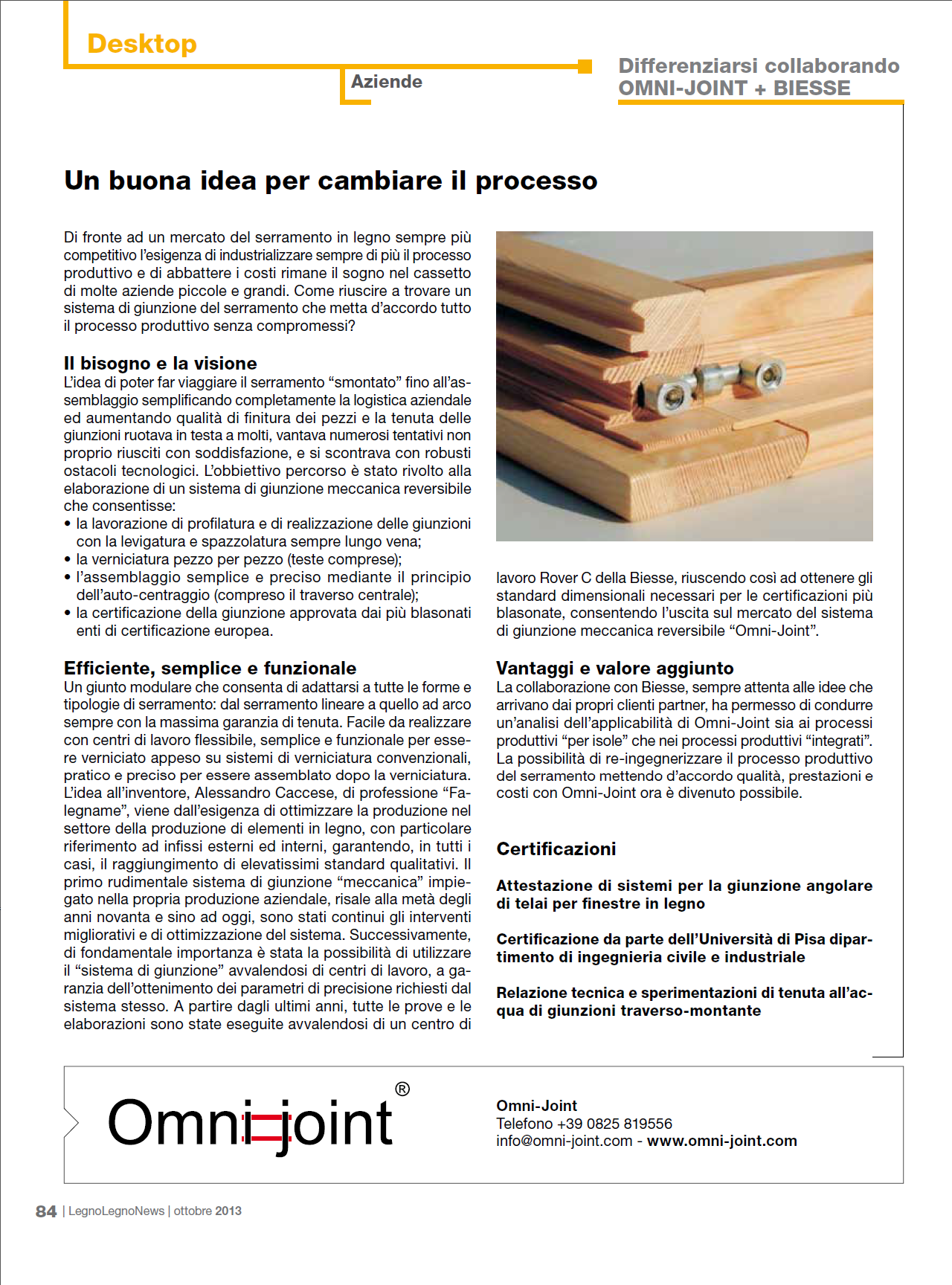

Many have thought about the possibility to transport disassembled fixtures until the assembly phase, simplifying completely business logistics and enhancing the quality of finish of pieces and the sealing of joints; in this respect, in the past, many attempts have failed, owing to big technological obstacles. The efforts have been directed to create a reversible mechanical jointing system that would allow the following advantages:

- the profiling process and the making of joints with sanding and brushing always along jamb;

- painting of single pieces;

- simple and accurate assembly by the principle of self-centring (including the central crosspiece);

- the certification of the joint was approved by the most important European certifying authorities.

Efficient, simple and functional

A modular joint that is compatible with all forms and types of doors and windows: from linear doors and windows to arched ones, always ensuring maximum seal. It can be easily produced in flexible manufacturing systems. It is simple and functional so that it can be hung on conventional painting systems; it is practical and precise, so it can be assembled after painting. Alessandro Caccese, is the inventor of this solution. He produces wooden items and his idea was inspired by the need to optimize the production process of wooden parts, specifically concerning external and internal fixtures, always ensuring excellent quality standards. The first rudimentary “mechanical” joint system used in his business production dates back to the middle of the nineties; since then it has been constantly developed to optimize it. Subsequently, it was fundamental the possibility to employ the “joint system” in manufacturing systems, to ensure the satisfaction of the required accuracy parameters. Since the last few years, all the tests and the processes were performed using the Biesse’s Rover C manufacturing system, achieving the dimensional standards required by major certifications to place on the market the reversible mechanical joint system ” Omni-Joint “.

Benefits and added value

The collaboration with Biesse, which has always cared about the ideas coming from its partners has made possible to lead a feasibility plan for the Omni-Joint system concerning both the manufacturing process with production islands and the integrated production processes. The possibility to re-engineering the production process of doors and windows combining quality, performances and costs, has now become possible with Omni-Joint.

Certifications

Certification of systems for angle joints for wooden windows frames

Certification of the University of Pisa, Department of Industrial and Civil Engineering

Technical report and watertightness test of joint sealing the ac- qua of transom-mullion junctions.